Innovation — arguably the most important pillar of Simms’ overarching approach to product creation. The designers and developers that toil away on the third floor here at Simms’ Bozeman, Montana Headquarters constantly ask and more importantly, challenging themselves to come up with better, more efficient, and functional solutions to virtually every angling equation under the sun. When it comes to innovation, our team remains diligent and maintains a hard delineation between true advancement and gimmickry. Through our lens, an innovation serves a genuine purpose and solves a specific problem. Gimmickry on the other hand, is more or less a visual que that either doesn’t accomplish much, gets in the way, or doesn’t function at all.

Some innovations practically take shape overnight. And sure, some are nothing more than happy accidents. However, in the case of the Simms’ all-new Confluence Stockingfoot Wader – neither is the case. The innovations anglers will experience in this wader took years to develop and implement to our standards and no doubt are 100% deliberate.

While the Confluence comes equipped with popular/expected Simms features such as built-in neoprene gravel-guards, anatomically engineered left and right neoprene stockingfeet, an air-mesh suspender system, and a vast pocket array, there are two features to this wader that break the mold. The most obvious — a compression-molded neoprene knee construction — and the not so visually obvious stretch fabric that the wader is built out of. The knee construction offers anglers additional protection while kneeling, brush-busting, and freedom of movement previously unmatched in waders while the stretch fabric provides distinguishable comfort, range-of-motion, and mobility.

As mentioned above, the knee construction, or what it’s more commonly referred to as, the kneepad, is not an innovation that happened overnight. In fact, this feature is something Clay Krull has been experimenting with since 2016. Clay’s tenure at Simms began back in xxxx. Through the years, Clay has become more than familiar with virtually every process and nuance of wader making. Currently serving as Simms Wader Development Manager, Clay’s design and development fingerprints are all over the new Confluence Wader. “Kneepads in waders is somewhat divisive — anglers either want them or they don’t,” says Clay. “With that said, when I look back at the early development days of this project, I really look at Confluence as a platform that allowed us to advance and implement new innovation throughout.”

Full transparency — the earliest attempts to incorporate knee pads into Simms waders heavily favored the gimmickry end of the spectrum. We tried stick on overlay kneepads, we tried placing them between layers of fabric, we tried them as inserts, the list goes on and on. No matter what we did, they just didn’t function properly — they were burdensome, they were uncomfortable, or they got in the way. However, the stall of the project began gaining traction when the product team approached the problem with a fresh POV. They realized kneepads as a product feature simply wasn’t going to cut it — they needed to incorporate a knee construction into the actual wader itself.

“Where the pad is located on the wader is actually a very challenging development problem to solve for,” says Clay. “You’ve got the structural difference of fabric vs. solid to contend with and you also have to be cognizant of where to place it in relation to where you want it to work. And not to mention, that particular area just so happens to be the area of the wader that receives the most consistent abuse. So obviously, the construction had to be completely dialed.”

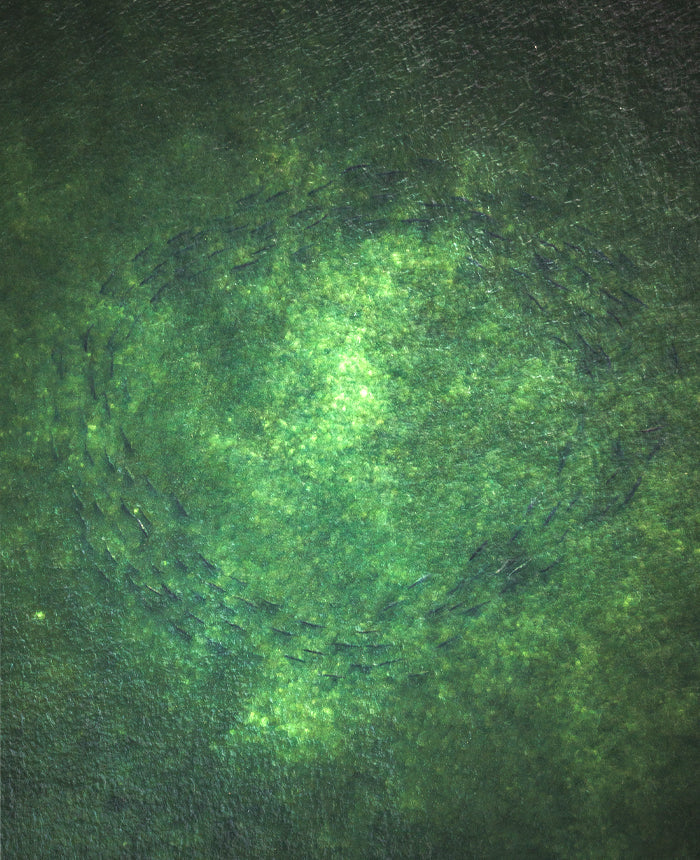

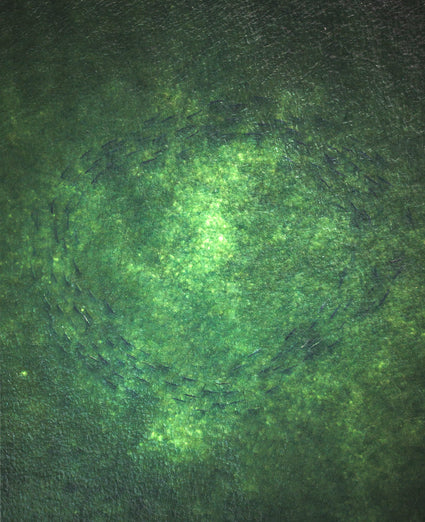

The best way to describe how the knee construction is incorporated into the wader is to think of it as an inlay or as if it’s integrated into the fabric. A tailormade hole is cut into the wader that the knee construction is nested in. On the inside, the outer perimeter of the knee construction is neatly bonded to the fabric in a similar fashion to how we attach our neoprene stockingfeet to our waders. The end result is an incorporated knee construction that moves and flexes in a way that accommodates that natural motion of the body.

The knee construction not only offers comfort and protection while kneeling down for stealthy presentations and/or releasing fish, it also provides a greatly enhanced range of motion in an extremely active area of the wader. Combine that aspect with a 4-layer Toray stretch fabric package and you’ve got a wader that offers next-level mobility all the way around. Prior to its release, the only wader featuring stretch fabric was the Women’s G3 Guide Wader in the side panels of the upper. While the Confluence isn’t Simms first foray into the utilization of stretch fabric in a wader, it is the first time it’s been used to this extent.

According to Clay, the Confluence went through roughly 12 iterations before its launch. At least 25 were sent into the field and were brutally tested in Montana, Colorado, New Zealand, Washington, Oregon, and Patagonia over a two-year span. After thousands of hours of rigorous testing, the approval ratings were through the roof across the board.

So who is the Confluence Wader for? Or perhaps a better way to phrase the question would be: What type of angler is the Confluence Wader built for? Whether it’s sunup to sundown missions in the backcountry or jumping in and out of a drift boat all day, the Confluence is built for anglers that move a lot. But then again, it’s also built for anglers that plain and simple have longed for a little extra cushion in the knees — an easily overlooked luxury, until now.